What is an undercarriage overhaul all about? Part 2: partial or complete overhaul in the workshop

During a partial undercarriage overhaul the top and bottom rollers are not renewed and this is always to the detriment of the service life of the undercarriage to a greater or lesser extent. This is simply because the machine can operate for more hours when new components can bed in together properly and not affect each other’s wear resistance.

In addition, a partial undercarriage overhaul unfortunately is mostly synonymous with temporary fixes. A quick repair may still be carried out in the field, but a proper and complete undercarriage overhaul needs to be done in a workshop.

Undercarriage overhaul in the workshop

When a machine comes in for a complete overhaul, it is jacked up to get it off the ground. Experienced professionals then make use of the most modern and innovative equipment to wash the undercarriage thoroughly and to clean the track shoes. Only then can all bolts be removed using an impact wrench so that the shoes can be removed.

Before that, the chain is laid out on a conveyor to make it easier to handle. This is almost impossible to achieve during on-site service, and is not an ergonomically sensible practice either.

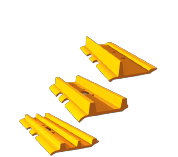

An undercarriage overhaul calls for specialist knowledge and equipment. It is a task for professionals. They assess whether the grousers (also called the teeth of the track shoes) have sufficient length to be refitted again. If that is not the case, the removed track shoes are replaced. After all, the grousers dictate the strength of the shoes.

Undercarriage parts that need to be replaced

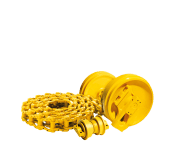

While two professionals are continuously screwing on the chain’s shoes during the undercarriage overhaul, another pair of professionals starts dismantling the other undercarriage parts that need to be replaced, which includes the top and bottom rollers, idlers with tensioning units, chain guides and sprockets.

To safeguard the installation quality of the new components, this pair ensures that the mounting surfaces are clean and smooth to ensure 100 percent alignment. Before assembly, the track adjusters of the tension devices are also fitted with new seals, to avoid dirt infiltration, among other functions. Experience shows that not replacing seals often leads to leaks. The tensioning rod is also polished.

After these operations, the idlers can be reattached to the tension devices and, when the guides have again been smoothly welded, placed back in the undercarriage. This allows the front wheel to move freely again to absorb the differences in tension on the chain.

In the next part, we will tell you more about quality and capacity of the undercarriage parts, the impact on the service life and the dos and don’ts during an undercarriage overhaul.

Vematrack

Get the job done We build further on our parent company’s more than 60 years of experience and develop new knowledge by specialising in the production of our own undercarriage components. We are happy to share the knowledge we have gained with machine users.Products that get the job done

Sprockets &

Segments

Track links

Bottom &

Top rollers

Track shoes

Rubber tracks

Rubber pads

Idlers

Tension devices

Track guards

Bucket teeth &

Wear parts

Bolts & Nuts