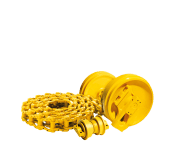

Vematrack track links for excavators & bulldozers

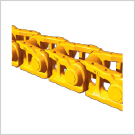

Greased track links

Excavator track links may be sealed or unsealed, and may be greased. Almost all VemaTrack track links are greased and sealed to guarantee a longer service life. The advantages of sealed track links are:

- The seals prevent soil infiltration and keep the grease in the track links.

- The pins are greased before pressing, so that they are resistant to weather influences and corrosion.

- There is minimal play between the pin and the bushing, thus preventing premature wear.

This combination results in a 20% longer service life for the excavator track links.

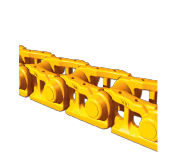

Oil lubricated track links

Bulldozer track links are usually oil lubricated. All bulldozer track links have a split master, a track link-joint which consists of two separate parts that fit into each other. There is more play between the pin and the bushing than with greased track links. After the pin is pressed, the space between the pin and the bushing is vacuumed and filled with oil. This ensures that the space between the pin and the bushing is filled optimally with oil. This also serves as a check to see whether the track has a perfect seal. So a proper seal is essential for preventing wear to an oil lubricated track.

Vematrack seals

We have designed special seals for our VemaTrack chains using an intensive duration test. We use these robust seals on all bulldozer chains. This prevents oil leaks and guarantees a long service life.

How can you recognise the wear patterns of tracks?

A track link is worn when there is so much play between the pin and the bushing that other undercarriage components start to wear. An increase in pitch creates more play between the pin and the bushing. This makes the inside of the bushing oval and the pin becomes thinner, because the it rubs against the bushing wall. This makes the track link longer. You can recognise an increase in pitch by e.g. the following visible characteristics:

- The points of the sprockets or segments become sharp, this is a sign that the track link no longer runs in line with the cogwheel due to an increase in pitch.

- The idler and its guide come out of the frame.

- The spaces between the track shoes and the links open up.

Because bulldozers do more mobile work, the undercarriage components of bulldozers will wear more quickly than those of an excavator.

Moreover, the link height defines the degree of wear. This in combination with the running surface diameter of the rollers. The pin heads may never touch the roller flanges.

Would you like more information, or request a quote?

Are you looking for track links/chains/tracks for the undercarriage of your excavator or bulldozer? ook to the right side of the page (or beneath) to the quotation form in the list of machine brands and find the brand you are looking for. First select your brand and type of machine, and then select the products for which you would like to receive an obligation-free quotation.

Why vematrack aftermarket undercarriage components?

- Fast delivery

- Largest supply

- Always competitive prices

- All brands & types

- Reliable

I am looking for track links for the brand:

Products that get the job done

Sprockets &

Segments

Track links

Bottom &

Top rollers

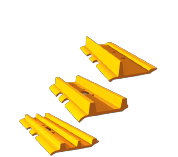

Track shoes

Rubber tracks

Rubber pads

Idlers

Tension devices

Track guards

Bucket teeth &

Wear parts

Bolts & Nuts