Mini excavator with rubber tracks vs. steel tracks: which is the best choice?

A mini excavator with a tracked chassis can drive on rubber tracks or steel tracks. But which one is better, rubber or steel? The choice of track depends on a number of factors and both options have advantages and disadvantages. Below, we discuss both options and the pros and cons.

Machines with rubber tracks

Machines with a rubber track undercarriage are mainly used on hard surfaces, usually in the construction, industry or agricultural sector. Important advantages of rubber tracks are:

- There is generally less vibration in a machine with rubber tracks (depending on the circumstances, of course), which makes the ride more comfortable for the operator of the machine.

- Rubber tracks do not damage the surface and hardly leave any marks.

- Machines with rubber tracks make less noise than machines with steel tracks.

However, there are also some disadvantages to machines running on rubber tracks:

- If used incorrectly, rubber tracks are more likely to be torn by hard or sharp objects on the ground.

- Driving on a wet or muddy surface with rubber tracks is less easy. A stronger material, such as steel, is a better option for this purpose.

Machines with steel tracks

Machines with steel tracks are generally used in situations where the machine has to walk on a less flat and hard surface, like mud, sand or in demolition. There are some important advantages to steel tracks:

- As mentioned before, steel tracks are ideal when your machines has to work on soft or wet ground, like sand or mud.

- You can choose the width of the track plates yourself. This is especially ideal when you have to walk on soft or wet surfaces. The wider the plate, the more bearing surface.

- Steel tracks are more durable. The strong material can better withstand hard and sharp objects and will not break as easily as rubber. Therefore, they do not need to be replaces as often.

There are also some disadvantages to a machine that runs on steel tracks:

- The steel tracks on a machine causes more vibrations, which make it less comfortable for the operator.

- Because of the vibration, the machine will also make more noise on hard surfaces.

- Steel tracks are more likely to leave marks on the ground they run over.

Which track is the best choice?

Both rubber tracks and steel tracks have advantages and disadvantages. The choice between a rubber track and a steel track undercarriage therefore mainly depends on the surface and the application of your machine. Does your machine mainly operate on hard and flat surfaces? In that case, rubber tracks are the best choice. Do you mainly work with your machine on a rough or soft surface? Then steel tracks are probably a better option.

In doubt? Feel free to contact us, we will be happy to help you!

PRODUCTS THAT GET THE JOB DONE

Sprockets &

Segments

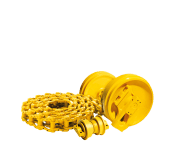

Track links

Bottom &

Top rollers

Track shoes

Rubber tracks

Rubber pads

Idlers

Tension devices

Track guards

Bucket teeth &

Wear parts

Bolts & Nuts

Complete undercarriages