Vematrack rubber pads for

excavators & construction equipment

Vematrack rubber pads are available in several types:

- VemaTrack Clip-on rubber pads: these rubber track pads are as it were clamped around the shoe.

- VemaTrack Bolt-on rubber pads: these rubber track pads can be screwed onto the track shoes. VemaTrack™ provides track plates with holes for the bolt-on pads in order to provide a complete solution.

- VemaTrack chain-on rubber pads: these rubber track pads are mounted directly onto the chain. In addition to the standard chain-on pads, we also supply HD VGRIP chain-on pads.

- HD VGRIP chain-on rubber pads are even more wear-resistant than standard VemaTrack™ chain-on pads. These pads also have an extension at the front (VGRIP), which prevents materials such as sand, stones and gravel from getting into the undercarriage.

- VemaTrack polyurethane chain-on: in this case, the polyurethane is directly poured onto the track shoe. This material has excellent resistance to wear, is pressure-resistant, is very resilient and is resistant to e.g. oils, petrol and greases.

- Polyurethane road pads: the polyurethane is poured directly onto the track plate. This material is extremely wear-resistant, suitable for heavy machinery, has great resilience and is resistant to, for example, oils, petrol and grease.

- Rubber road pads: have more grip than polyurethane pads.

Quality retention

The most important thing about a rubber track pad is the adhesion of the pad’s rubber to the steel. For optimal adhesion of the pad, a coating must be applied to the steel. This coating ensures that any rusting process in the steel is reduced to a minimum. If the coating is not done, or not done properly, cracks may form. This may cause the pads to come loose. In short, the coating prevents unnecessary wear to the steel tracks with rubber track pads.

How can you recognise the wear patterns of rubber track pads?

Rubber track pads are used when the substrate, e.g. the asphalt or pavement, may not be damaged. If the steel parts protrude through the rubber due to pad wear, then it is time to replace them. If they are not replaced, the steel parts will still damage the substrate.

Would you like more information, or request a quote?

Are you looking for pads for your excavator or other construction equipment? Look to the right side of the page (or beneath) to the quotation form in the list of machine brands and find the brand you are looking for. First select your brand and type of machine, and then select the products for which you would like to receive an obligation-free quotation.

Why VemaTrack aftermarket undercarriage parts?

- Fast delivery

- Largest supply

- Always competitive prices

- All brands & types

- Reliable

I am looking for rubber pads for the brand:

Products that get the job done

Sprockets &

Segments

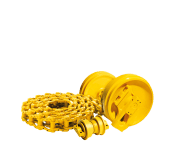

Track links

Bottom &

Top rollers

Track shoes

Rubber tracks

Rubber pads

Idlers

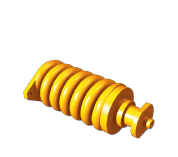

Tension devices

Track guards

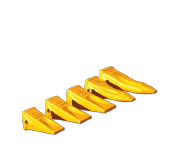

Bucket teeth &

Wear parts

Bolts & Nuts

Complete undercarriages