Frequently asked questions

The undercarriage of your excavator can be quite complicated. We therefore regularly receive questions on this subject. We have answered the most frequently asked questions about undercarriage below.

Perhaps the answer you are looking for is in here. Is that not the case? Feel free to ask us your question by phone or e-mail. We will be happy to help you further.

Questions about rubber tracks

When should I replace my rubber tracks?

The rubber tracks of your undercarriage will eventually wear out, which cannot be avoided if you use your excavator often. It is important to replace your rubber tracks in time when they are worn out, otherwise you may get damage to the machine or other undercarriage parts.

You can recognise the wear on your rubber tracks in several ways, you can read all about it in our blog on the subject.

How do I recognise the wear on my rubber tracks?

Your rubber tracks will eventually wear out when you use your excavator a lot. This wear can be recognised by a number of factors, which you can read on the page about our rubber tracks.

How can I tell the difference in quality with rubber tracks?

The difference in quality with rubber tracks is almost imperceptible, this is mainly in the inside. The quality of a rubber track depends on several factors:

- The amount and type of cables used for the inserts

- The composition and quality of the rubber used

- The number and thickness of steel cables in the tracks

What are the advantages of AVT Rubber Tracks?

AVT (anti-vibration tracks) contain cams in the form of wyberts, so there is continuous contact between the rollers and the cams. This has a number of advantages:

- Up to 75% lower vibration level;

- There is more comfort for the operator;

- Less wear on the undercarriage. This is especially at the idlers, sprockets and top and bottom rollers).

How long will my rubber tracks last?

The lifetime of your rubber tracks depends heavily on a number of factors, such as the driving and running hours of your excavator, the surface you work on and the width of the track shoes. Read more about the lifespan of your rubber tracks in our blog.

How do I recognise wear on rubber tracks?

- Cracks in rubber tracks: Cracks can occur when the tracks drive over sharp objects, such as construction debris, metal objects or rubble. If the crack is so deep that the iron is visible, moisture can get through it, causing rust. This ultimately increases the likelihood of the rubber tracks breaking.

- Drying out due to UV light: Prolonged exposure to UV light can reduce the rubber quality of tracks. To prevent drying out, it is recommended to store the tracks in a sheltered place.

- Decrease in tread: As with car tyres, the profile of rubber tracks can become thinner due to exposure to sharp objects or excessive pressure. This process is part of wear and tear and can be detrimental to the track’s grip and stability.

How can I extend the life of my rubber tracks?

You can extend the life of your rubber tracks in several ways:

- Handle the correct tension of the tracks.

- Avoid driving on sharp objects that can damage the tracks.

- Limit running on hard surfaces, this reduces wear.

- Keep the tracks clean after use.

- Store the excavator properly when not in use.

- Choose the appropriate type of track for the application.

- Avoid overloading the tracks.

- Regularly inspect for wear to avoid premature replacement.

How do I know which rubber tracks fit my excavator?

Rubber tracks are often custom-made for one particular type of excavator. On verhoevenrijwerk.nl you can easily search for the right track by entering the brand, type, model and serial number of your excavator. Most tracks indicate the dimensions, so you can easily find a replacement track.

Can I replace rubber tracks myself?

Replacing rubber tracks can be done yourself, however this does have its pros and cons.

Advantages:

- Cost savings

- Time savings

- Flexibility in scheduling

Disadvantages:

- Tools and equipment required

- Technical knowledge required

- Safety risks when working with heavy excavators

What does it cost to replace rubber tracks?

Depending on the type and size of track, the price varies greatly. Use the search function on our website to find the right tracks for your excavator, or contact us for personal advice.

Questions about undercarriage parts

How do I recognise the wear on my undercarriage parts?

You may be in doubt whether your undercarriage parts need replacing already, or whether you can still work with them for a while. In our blog, we tell you how to recognise wear on chains, track links, rubber tracks, track shoes, rollers and more.

How do I replace my undercarriage parts?

Want to replace your undercarriage parts yourself, but don’t know exactly how to do it? We have a lot of blog posts on our website that might help you further. Still can’t figure it out? Then feel free to contact your local dealer.

What is the correct tension of the tension device on the tracks?

For the correct tension on your rubber tracks, it is best to look in the excavator’s user manual. This is because it lists the voltage the manufacturer describes as correct and the different ways you can measure it.

Which rubber pads are best for the steel undercarriage of my excavator?

Rubber pads are mounted on a steel undercarriage to prevent damage to the surface as much as possible. There are different types of pads, all of which can be used for different applications. Read in our blog which pads are best for your job.

How do I mount my track links correctly?

To mount the track links in the right direction, it is important to know what the front and rear of the undercarriage are. The idlers are at the front of the excavator, while the sprockets and travel drives are at the rear.

Then it is important to stick to the picture below. When the track link is open on the ground, it looks like the picture. A link has a narrow and a wide side. The wide side belongs on the sprockets side (back of the undercarriage) and the narrow side belongs on the idler side (front of the undercarriage).

Still not quite clear? In our blog, we give more reminders that will help you determine the correct direction of travel for your track links.

How long will my undercarriage last?

This question is difficult to answer. In fact, it depends very much on a number of factors, such as the driving and running hours of the machine, the surface it runs on and the maintenance you do to your undercarriage. You can read more factors that affect the lifespan of your excavator in our blog.

How does the mobile track press work?

VemaTrack’s portable track press makes it possible to quickly, easily and safely press a pin out of an undercarriage track link. Using the track press has some great advantages, you can read these in our blog.

Want to know how the portable track press works? Then watch the track press video on YouTube.

Is it better to choose a steel undercarriage or rubber tracks for my mini excavator?

That choice depends on a number of factors. Both a steel and rubber undercarriage have advantages and disadvantages.

For example, a major advantage of rubber tracks is that they do not damage the surface and make less noise than steel undercarriage. Moreover, driving on rubber tracks causes less vibration, which is more comfortable for the operator. However, rubber tracks are less suitable for driving on wet or muddy ground, and they are more likely to crack due to hard or sharp objects on the ground.

If you drive your excavator a lot over soft or wet ground, then steel tracks are a better option. Moreover, steel tracks are more durable, as they are less likely to break down. However, steel tracks make more noise and cause more vibrations, which is less comfortable for the operator. In addition, steel tracks leave more marks on the surface.

What is the difference between short pitch and long pitch rubber tracks?

When looking for new rubber tracks, you usually don’t have a choice between short pitch or long pitch rubber tracks. This is because most excavators can only run on one of the two.

Short pitch rubber tracks have shorter lugs, allowing the rubber track to engage each tooth of the sprocket. This reduces vibration and undercarriage wear.

Long pitch rubber tracks have longer lugs, allowing it to skip a tooth in the sprocket each time. As a result, long pitch rubber tracks have less packing in sandy soil, which in turn is an advantage in certain operations. On the other hand, the excavator runs less quietly and the undercarriage will wear faster.

What causes wear on sprockets?

There are several causes of wear on sprockets:

- Normal use: Wear from regular use.

- Incorrect track tension: Incorrect tension accelerates track wear.

- Uneven load or misalignment: This leads to uneven wear of the components.

- Poor maintenance: Regular maintenance helps prevent wear.

- Improper installation: Incorrect installation can accelerate wear of the sprockets.

How often should sprockets be replaced?

It is recommended to replace sprockets when changing tracks. This ensures optimal cooperation between the parts.

How can I extend the life of my sprockets?

How can I extend the life of my sprockets?

The life of sprockets can be extended by:

- Performing regular maintenance to reduce wear.

- Keeping tracks at the correct tension to minimise load.

- Preventing overloading.

- Using the right parts tailored to the particular excavator.

Can I replace sprockets myself?

It is possible to replace sprockets yourself, but this requires specialised tools, equipment and technical knowledge. In addition, it is a risky job that requires compliance with proper safety measures.

What does it cost to replace sprockets?

The cost of replacing sprockets varies greatly depending on the excavator they are made for. On the Verhoeven Undercarriage website, you can use the search engine to easily find the right sprocket for your machine.

Questions about quotes

How do I request a quote for undercarriage parts?

Requesting a quote for undercarriage parts is very simple. Contact the dealer in your area via our contact page. If you cannot find a dealer in your country, or there is no available dealer? You can also contact VMT International directly.

Producten die de klus klaren

Sprockets &

Segments

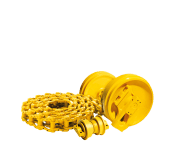

Track links

Bottom &

Top rollers

Track shoes

Rubber tracks

Rubber pads

Idlers

Tension devices

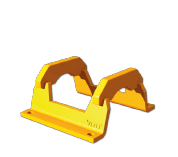

Track guards

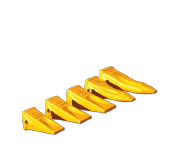

Bucket teeth &

Wear parts

Bolts & Nuts

Complete undercarriages