3 factors that determine the lifecycle of your crawler undercarriage

“My crawler undercarriage has been running for 8000 hours. You probably won’t get over that!” – Drivers regularly brag about the number of hours they have been running their crawler undercarriage. But there are also machine owners who wonder why their machine’s crawler undercarriage has been running for so few hours. It makes sense to have the worn parts of the crawler undercarriage properly inspected for wear patterns. This often produces results that ensure that you look at your crawler undercarriage from a different perspective in future. We can help you with this by explaining three important factors that determine the lifespan of a crawler undercarriage: the surface on which you are working, the distance you travel and your machine’s direction of travel.

1. Surface

A very important aspect in a crawler undercarriage’s wear time is its use in certain areas. Anyone who uses a steel crawler undercarriage in sharp sand knows that a crawler undercarriage will wear out faster than on a loamy surface. If you use your wide caterpillar tracks in the demolition area and you ride over a heap of broken material, then you will have an impact on the connections between your chains’ pin and bushing. The narrower the caterpillar tracks, the lower the impact on the connections and the longer your chain will keep going.

2. Distance

The current machines are all equipped with digital hour meters and setting options. You can also see the number of flow hours that have passed from the hydraulic pump to the drives. The crawler undercarriage runs at a speed of 3 to 6 km/hour and achieves an average of 800 driving hours. That means that a crawler undercarriage has driven an average of 2400 to 4800 km before the chains are worn out. So if you were to drive your machine continuously, this amounts to 800 working hours, or 100 days in a row (8 hours working time). Machines that, on the other hand, are on a pontoon and therefore not moved (or only rarely driven up and down) achieve much higher numbers of operating hours on the counter. These do not cover distances when we look at the hourly flow counter from the hydraulics to the final drives. Machines with the most hours running at low speed generally have better results than the machines that run at high speed. Do you have a lot of work that needs to be done while driving? Then consider buying a tyre crane or a wheel loader and get the crawler crane to carry out as much stationary work as possible.

3. Direction of travel

The driver can make a significant difference to the amount of wear if he drives the machine forward as much as possible. The bushing will wear twice as fast when the machine is reversing. This is because the link to which the bushing is attached, after the sprocket tooth has taken the bushing into its bend, should also rotate around the sprocket. The link with a caterpillar plate firmly attached to the bushing causes a rotating movement in the bend.

Do you want better results?

It makes sense to look for the optimum crawler undercarriage specifications for your machine together with your dealer. The use of the machine, the surface area and the type of activity play a key role here. A small adjustment can make a quick improvement. There are a number of options that can help with this. For example, you can chamfer wide caterpillar plates with the result that the crawler undercarriage meets less opposition on a harder surface to sliding sideways over the floor plate. There is less stress on the pin and bushing connection and also therefore less chance of a gap or less chance that dirt will infiltrate between the pin and bushing with all the consequences that involves.

Every machine is unique. You will never find two machines that have been operating identically in the same conditions, on the same surface areas and at the same speed. Operators are never the same and where one goes slowly, the other thinks “Go flat out!”. As a result, it is not possible to compare machines’ total hours with each other – without looking at how the machine was used. Has this been used for working from the slewing ring or just for activities that require a lot of driving? One thing is certain: the well-maintained and regular cleaning of a caterpillar chassis results in its lifespan being extended. Are you considering buying a new crawler undercarriage or machine, and do you want to be sure of optimum results? Then contact your VemaTrack dealer for appropriate advice.

PRODUCTS THAT GET THE JOB DONE

Sprockets &

Segments

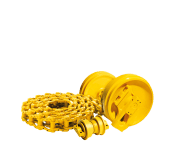

Track links

Bottom &

Top rollers

Track shoes

Rubber tracks

Rubber pads

Idlers

Tension devices

Track guards

Bucket teeth &

Wear parts

Bolts & Nuts

Complete undercarriages