Which rubber pad is the best choice for your steel undercarriage?

You have seen them before: an excavator fitted with rubber pads on the steel undercarriage. They are machines that often drive on hard surfaces and where steel track shoes would cause too much damage. Actually I am starting off wrong and should write “pads” on a steel undercarriage as it is more than just a rubber pad. Let us first look below at what types exist and the different applications for which they can be used.

Types of (bolt-on) pads

There is a pad that best suits every type of work, compare this with the shoes on your own feet: you don’t go running in rubber boots, or climb a mountain in flip flops. The same applies to pads on the chain of an excavator. First and foremost we can make a distinction between pads that are bolted either directly onto the chain, or onto the track shoes. Depending on your application you can then choose from rubber or polyurethane pads (PU pads). We list all the advantages and disadvantages for each rubber track pad.

Clip-on pads

A clip-on pad is a vulcanised (rubber-coated) steel plate which you clamp onto your existing track shoe by means of brackets. These are available in the most common chain pitches from pitch 190 mm to 700 mm.

Advantages

- Cheapest option

- Quick to fit/remove

Disadvantages

- May come loose easily

- Not made for intensive use

Chain-on pads

A chain-on pad is also a vulcanised steel plate, the difference being that you screw this directly onto the chain – just as you screw it onto the track shoe. The chain-on rubber track pad is available in the most common pitch sizes and widths.

Advantages

- Best price/quality option

- Durable solution

- Suitable for intensive use

Disadvantages

- Machine cannot easily be used on another surface: changing to track shoes or vice versa is time-consuming

- Track shoes are collecting dust in your warehouse, until you convert your machine again or decide to sell it

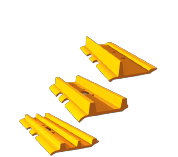

Road pad

A road pad is in fact more than a vulcanised track shoe; you can recognise it from the typical curved wedge that typifies a track shoe. The road pad is available in the most common pitch sizes and widths. Rubber asphalt pavers and PU for milling machines

Advantages

- More expensive option

- Extremely sustainable solution

- Suitable for intensive use

- High stability of the machine due to the rectangular (rubber/PU) support

Disadvantages

- Machine cannot easily be used on another surface, changing to track shoes or vice versa is time-consuming

- Track shoes lie collecting dust in your warehouse, until you convert your machine again or decide to sell it

Bolt-on pads

The bolt-on pad is the last option. This is also a vulcanised steel plate that is fitted by means of four integrated threaded ends through the holes provided in the track shoes. Available in a chain pitch from 190 mm to 800 mm.

Advantages

- Extremely durable solution

- Shaped over the grousers for a perfect fit

- Suitable for intensive use

- Quick to fit/remove due to the four easily accessible nuts

- Rubber crumbles less because there are no more holes in the middle of the plate

Disadvantages

- Most expensive option, because you have a one-off cost item from the extra drilling of the existing track shoes.

Polyurethane

As described above, some solutions, such as the road pad, are available in a polyurethane version (left) as an alternative to the rubber version (right). The PU version of the road pad is particularly suitable for asphalt pavers.

PU is a copolymer (plastic compound of two elements) that consists of a hard and a soft element, bonded into a chemical chain. By changing the composition of the chain, you can adapt the properties of the PU to the needs. For example PU can be extremely flexible and still be very wear resistant.

Where the rubber version has an excellent grip, the PU version is again extremely suitable for use in acid/base environments due to its high resistance to various chemicals. These can also withstand temperatures from -35 °C to +100 °C.

Now that you know the advantages and disadvantages of all the different options of rubber track pads, it will be easier for you to choose from our range. If you have any other questions, please contact your closest dealer. You can find its location easily via the dealer locator.

Chris Salaj

Salesman VemaTrack We build further on our parent company’s more than 60 years of experience and develop new knowledge by specialising in the production of our own undercarriage components. We are happy to share the knowledge we have gained with machine users.PRODUCTS THAT GET THE JOB DONE

Sprockets &

Segments

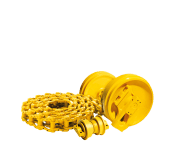

Track links

Bottom &

Top rollers

Track shoes

Rubber tracks

Rubber pads

Idlers

Tension devices

Track guards

Bucket teeth &

Wear parts

Bolts & Nuts

Complete undercarriages