Maintenance of rubber tracks

A mini excavator is a versatile vehicle for various terrains. To properly maintain the tracks and know when to replace them, here are some guidelines.

The right time for track replacement/change

The process of replacing or changing tracks involves lifting the mini-excavator with the boom and dozer blade, after which grease can be collected from the grease tensioner by unscrewing the grease nipple. The track can then be loosened at the rear.

Inspection of sprockets

Check the sprockets’ teeth for wear during track replacement, as worn teeth can cause slippage in the track. If necessary, replace the sprockets and use new bolts for sturdy mounting.

It is also important to correctly tension the tracks. This depends on the surface. A hard surface requires more tension than a softer one such as sand.

Correct tensioning of the tracks

Oil change

The hydraulic motors that drive the tracks run in an oil bath. This oil should be changed every 500 hours. Use the drain plugs on the sprocket cover to drain and change the oil, collecting and disposing of the oil according to the instructions.

Daily maintenance

Checking daily for damage to the undercarriage is essential, as hard objects can cause damage. It is important to check daily that there are no sticks, stones or pieces of iron in the running gear. If there is a lot of loose soil in the undercarriage, lift the undercarriage off the ground using the boom and dozer blade and run the tracks for a short time. This way, the mini excavator’s undercarriage will come off the ground by itself, which will help in removing loose soil and debris.

Positioning the tracks

These guidelines will help you keep your mini excavator’s tracks in optimal condition. For detailed instructions, consult the instruction booklet or click the button for a step-by-step guide.

Want more information on maintaining your rubber tracks? Then contact your local VemaTrack dealer.

PRODUCTS THAT GET THE JOB DONE

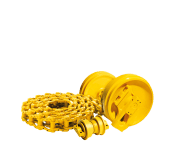

Sprockets &

Segments

Track links

Bottom &

Top rollers

Track shoes

Rubber tracks

Rubber pads

Idlers

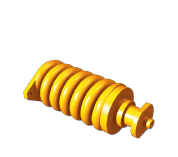

Tension devices

Track guards

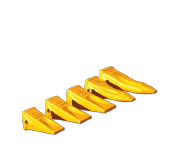

Bucket teeth &

Wear parts

Bolts & Nuts