How long will my undercarriage last?

One of the questions that is asked during basically all sales talks regarding undercarriage parts is how long the undercarriage will last. Unfortunately, we cannot answer this question directly since this will depend on many factors that all have an impact on durability. On an annual basis, we see more than 350 machines in our workshops that are given new undercarriage parts. So now and again we see one returning that was overhauled 4 to 8 years ago. This teaches us a lot about how long your undercarriage can last. In the text below we will give you the Undercarriage Wear Guide: How do you recognise the wear on your undercarriage?

Driving and operating hours of your machine

The latest machines have somewhat more information on their screens than just the traditional analogue hour meter. With regard to a Liebherr R906 (24T machine) with a total of 8603 operating hours, we can read what the machine has driven by simply clicking a few times in its menu. You can see this too on the photo above: The machine has operated for 180.9 hours in the fast-hare-setting (6.1 km/h) and 695.1 hours in the slow-tortoise-setting (3.7 km/h).

This means the following:

- 9 hours x a high speed of 6.1 km/h = 1103.49 km

- 1 hours x a slow speed of 3.7 km/h = 2571.87 km

This is a total covered distance of 3675.36 km, or: a round trip to Barcelona from the Netherlands. In accordance with the operating hour readings on the machine, it will take you 876 hours. Should you also perform work while standing still in the intervening time, the operating hours will go up, but the distance will stay the same.

Surface

The surface on which you drive is also an important factor that plays a role. If you need to drive over a demolition site filled with rubble, this will lead to more stress on the links than when compared to moving over a recently mowed field of grass. Grit and sea salt will significantly impact the steel parts that touch each other and the seals in-between the pin and bushing. In addition, loamy soils will easily penetrate into the tensioning unit after which they will significantly harden when dry. This will impact the tensions on the tracks and will lead to fewer driving hours. The driving hours can be maintained at an optimal level by very regularly cleaning the undercarriage.

Width of the track shoes

This can go completely wrong with logs.

The track shoes are secured onto the tracks with 4 bolts that are usually in the centre of the shoes. If you exert pressure on the corner of the track shoe, the bolts will ensure the transfer to the link of the track that can be found on this track shoe. The next track shoe can absorb pressure on the other side and therefore the next track link will again exert pressure in another direction. This leads to stress and friction in-between the 2 parts which is not good for the driving hours. If you decide to use shoes that are a size narrower, the pressure will be considerably lower and your driving hours will increase.

Direction of travel

Something that is difficult to explain is the direction of travel that has an impact on the driving hours. If you drive forwards and the tooth of the sprocket runs over the bushing of the track chain, the track and shoe rotate too in a positive manner. At the location where the bushing is attached to the correct side of 1 track link, it rubs once with its bushing wall against the sprocket’s tooth. When reversing, in the first instance, the sprocket’s tooth rubs along the bushing wall to pull the link. You can then say that the sprocket pulls on the wrong side of the track link because a rotating movement in the opposite direction will follow of the bushing after it is already in the sprocket. Double wear therefore occurs on the bushing when reversing. This will mean that the machine can drive less far.

Do you want to achieve more driving hours from your moving parts? We will gladly take a constructive approach with you about how you can achieve this! In addition to the above tips, there are more small interventions that will have a positive impact to keep the costs per operating hour of your machine as low as possible. Use our free-of-charge undercarriage inspections and request advice when you believe you should have got more out of your machine.

PRODUCTS THAT GET THE JOB DONE

Sprockets &

Segments

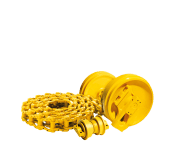

Track links

Bottom &

Top rollers

Track shoes

Rubber tracks

Rubber pads

Idlers

Tension devices

Track guards

Bucket teeth &

Wear parts

Bolts & Nuts

Complete undercarriages