A rubber track is more than a piece of rubber!

Everyone knows what a rubber track looks like – this black rubber tyre fitted around the undercarriage of mini and midi excavators. However, not every rubber track is the same. There is in fact a different type of rubber track for each application; short pitch, long pitch, AT, AVT… It may be called a “rubber” track, but the track does not actually consist of only rubber. There is much more to it than just some rubber.

Composition

I can hear you think: “So what’s so special about a rubber track?” You can indeed see only rubber on the outside. In the case of the VemaTracks rubber tracks, this is a special blend of pure natural rubber (1). Then you have a number of steel inserts, embedded into the rubber (2). The bottom rollers move over these are inserts. A long steel wire (3) runs along both sides of these inserts. The lugs (4) prevent your rubber track from slipping, while the sprocket engages around the bushings (5) and provides traction.

The choice of the steel for the inserts determines the wear resistance of your rubber tracks; the wider the inserts are, the tougher it gets. Narrower inserts will tear out of the rubber just as easily. The rubber track is less likely to stretch due to the long steel wire. For example, a steel wire of 4 mm runs twice through a VemaTrack rubber track of 300 mm width, making 20 turns (through the length of the rubber track).

A rubber track for every application

We have a rubber track for every application. Maybe you have heard of short pitch, long pitch and VemaTrack anti-vibration tracks? Let us first determine the dimensions of a rubber track, for example:

83.5 = the pitch, from lug to lug in mm

76 = number of lugs

450 = width of rubber track in mm

What about the short and long pitch? These are the short and long pitches of a rubber track. The number of lugs and the pitch are usually inversely equal to each other; when a long pitch is twice as long, it is half the number of teeth (and vice versa).

An excavator on the long-pitch will drive very restlessly, because the lower rollers constantly “fall” between the lugs. By using a short-pitch rubber track, the operator gains comfort in the cab while driving. This is because the lower rollers “fall” less between the lugs. If you really want to ride comfortably, you need the VemaTrack anti-vibration track. An anti-vibration track ensures that the bottom rollers run smoothly from one lug to the next. This is because the cams have a trapezoidal shape. This ensures that vibrations can be reduced by up to 75%.

However, packing is more likely to occur with an anti-vibration rubber track. Packing occurs when material accumulates between the lugs. The space between the lugs becomes so narrow that material (stone/earth/debris) may not be easily squeezed out by the sprocket. This in turn will increase the wear and stress (strain) on the rubber track.

Finding it hard to choose?

The difference in prices of rubber tracks can be found on the inside of the rubber track. Mainly the materials used determine the price and lifespan of a rubber track, rather than the quantity of rubber. When is it best to choose which rubber track?

- Short/long rubber track: When the machine is used mainly on ground with stone rubble or unpaved surfaces.

- Anti-vibration rubber track: When the machine is used mainly on paved surfaces.

There is a different type of rubber track for every application. If you have any doubts, please contact us. Together we will choose the best rubber track for your machine and application.

Chris Salaj

Salesman VemaTrack VemaTrack continues to build on over 60 years’ experience of its parent company and develop new knowledge by specialising in the production of its own under undercarriage parts. We like to share the knowledge we have gained about crawler undercarriages with those using the machines.PRODUCTS THAT GET THE JOB DONE

Sprockets &

Segments

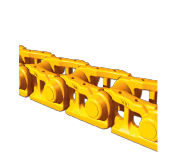

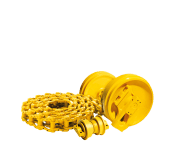

Track links

Bottom &

Top rollers

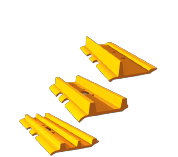

Track shoes

Rubber tracks

Rubber pads

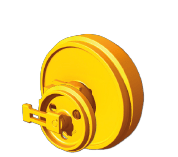

Idlers

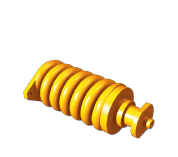

Tension devices

Track guards

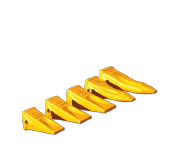

Bucket teeth &

Wear parts

Bolts & Nuts

Complete undercarriages