What is the right tension for the tracks?

Many undercarriage mechanics often resort to a little guesswork when it comes to getting the correct tension on the track adjuster of an undercarriage. However, there is actually only one guideline, and that is the machine’s operation and maintenance manual. This specifies the correct tension recommended by the manufacturer. Furthermore, the various ways in which this should be measured are even more important. To illustrate this, I have provided an example below from the manual for a Takeuchi, although the details will differ for other makes and sizes of machines.

The tensioner/track adjuster

The tension applied to the rubber tracks or chains can be regulated using the track adjuster. The track adjuster can be constructed in a variety of ways chosen by the machine’s manufacturer.

You can adjust the position of the front idler in relation to the frame by pumping grease into the track adjuster valve. You do this by using a grease gun to pump grease through the grease nipple into the track adjuster that is located on the track adjuster (which can usually be found behind the access cover). The rod that protrudes from the housing of the track adjuster valve allows the front idler to be positioned so as to apply the correct tension on the rubber tracks or chains.

If the tension on the tracks or chains is too tight, or you need to remove the tracks or chains from the undercarriage, then you can loosen the idler tension grease fitting to release tension from the track adjuster valve and bring the front idler inwards towards the frame. Slowly loosen the idler tension grease fitting, making sure that you do not loosen it too much as the valve is under a lot of pressure.

How do you check whether you have put the right pressure on a track adjuster?

Before you operate the machine, you should regularly check the tension of your chains or rubber tracks. Operators who know their machines well will already have a sense of whether this is correct when they step onto the chains or rubber tracks as they enter the cab. If the chains or rubber tracks sag, then the tension of the track adjuster may not be correctly adjusted. If you want to check the tension of your rubber tracks or chains, then in most cases, you should start by allowing the undercarriage to travel freely by jacking or raising it.

Once you have raised the undercarriage, roll the tracks or chains for a while in the forward direction. When you do that, the front idler will move as far forwards as possible, so it will be under the least amount of tension possible.

The tracks will sag below the undercarriage and you should measure the sag of the tracks or chains. You should do this in the correct way, as specified by the manufacturer, which is usually the same as in the example below.

Depending on the type of undercarriage, these measurements may vary, as a rubber track is lighter than a steel undercarriage with steel track shoes. If you have pads fitted to a steel undercarriage, the chain will naturally sag more below the undercarriage, particularly for heavier machines. Make sure that the undercarriage remains raised while taking the measurement.

You will then get a measurement for the undercarriage construction and the various types of bottom rollers, described above as A and B, where A is for rubber tracks, and B is for chains with track shoes.

Depending on the length of the rubber track, the weight of the machine, and the undercarriage construction, the manufacturer will specify how far the track may sag in order for it to travel perfectly below the undercarriage.

The correct tension

You can only find the correct tension in one place, and that is the manufacturer’s operation and maintenance manual for your model of machine. The manufacturer determines the tolerances for the ideal tension based on its experience and manufacturing. A very worn track or undercarriage part affects your driving experience. That is not to say that the track will travel better if you keep to the above measurements. It is just that these measurements will give the longest possible working life for the entire undercarriage from new. (provided these can be verified, as the tensioning rod of the track adjuster, the maximum possible strain on the rubber tracks or the pitch increase of the chains are not endless)

If you experience any problems once you have checked the tension, it may well be that there are other worn undercarriage parts. You can also find measurements for these in the operation and maintenance manual, or a VemaTrack dealer can provide advice for the steel undercarriage parts.

PRODUCTS THAT GET THE JOB DONE

Sprockets &

Segments

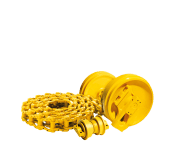

Track links

Bottom &

Top rollers

Track shoes

Rubber tracks

Rubber pads

Idlers

Tension devices

Track guards

Bucket teeth &

Wear parts

Bolts & Nuts

Complete undercarriages